Compared to trandistional Molecular sieves and adsorption wheels, our materials have higher adsorption and desorption rates. It is designed with micro-holes and multilayer structures with adjustable size and appearance.

| Drying Technology | Temperature/Time | Features | |

|---|---|---|---|

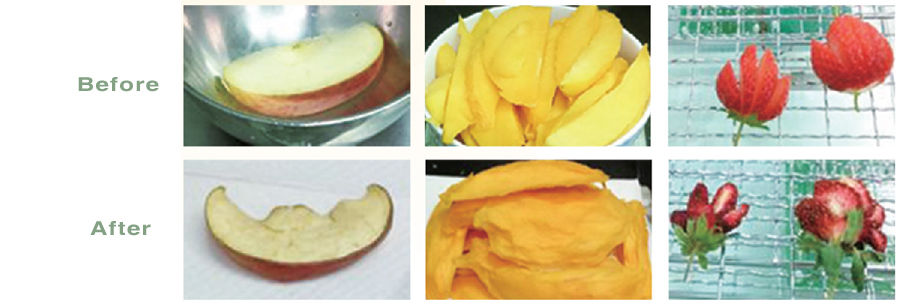

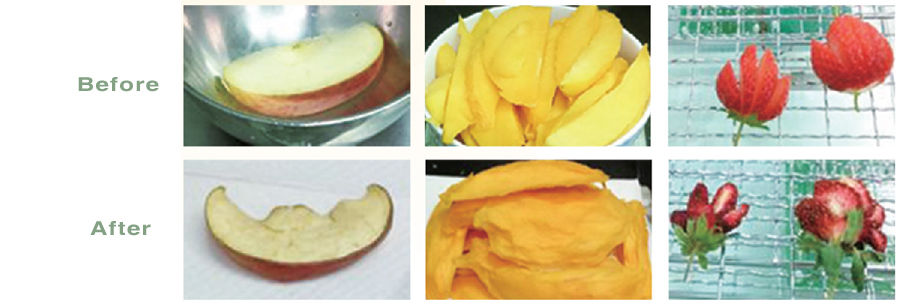

| Drying in Room Temperature (Aeromats) | Use adsorption technology to reduce air humidity to (1 - 5% RH) to dry fruit quickly without damage under nomal temperature. | 28 C to 35 C 12 ~ 48 hrs | Retains the fruit's aromatic composition, keeps the original color of the fruit, enzymes and nutrients (low engery consumption). |

| Hot Air Drying | Manually injects hot air and uses air circulation between hot and cold surfaces to dry fruits. | 45 C to 120 C 12 ~ 48 hrs | A shorter drying time increases lipid oxidation and protein change properties. A darker finished product, with increased browning and Loss of nutrients (high engery consumption). |

| Freeze-Drying | After freezing the fruit, a high vacuum is applied to cause water molecules to change directly from a solid to gas (sublimation removal method) | Can reduce the loss of volatile aromatic components including its color, fragrance, physical properties. The shape is intact. Good resilience, but higher equipment costs. Mostly applied to high economic value crops. |